solutions

德国维替阀门 2024-11-19 09:27 5797

China's annual coal consumption accounts for over 70% of its primary energy consumption, of which approximately 40% is used for coal-fired power generation. By the end of 2020, the total installed capacity was approximately 2.2 billion kilowatts, among which the capacity of coal-fired generators was 1.08 billion kilowatts, accounting for 64.7%.

In recent years, with the intensification of technological transformation in the global power generation industry, a number of super (super) critical units have been newly built, especially coal-fired power plants with economic performance at the world's advanced level. The overall economic level of coal-fired units has been greatly improved.

In order to enhance the economics of thermal power generation units and achieve energy conservation, emission reduction, consumption reduction and efficiency improvement, Weitai Industrial Valve Company has been making unremitting efforts to improve the structure and materials of valves. In recent years, Viti Industrial Valve Company has provided overall pipeline fluid control solutions for over 200 power generation enterprises under China National Energy Investment Group, including China Huaneng Group, China Datang Group and China Huadian Group. This has effectively enhanced the technical and economic level of China's power generation equipment and promoted energy conservation and consumption reduction.

The hazards of harsh working conditions in thermal power plants to industrial valves

The harsh working conditions impose higher demands on industrial valves. Once industrial valves suffer damage and experience leakage, the harsh working conditions will accelerate the leakage and damage of the valves, causing the high-quality medium that should be used for power generation in the steam turbine to leak and be wasted, directly resulting in economic losses for thermal power plants and increasing the coal consumption for power generation in power plants.

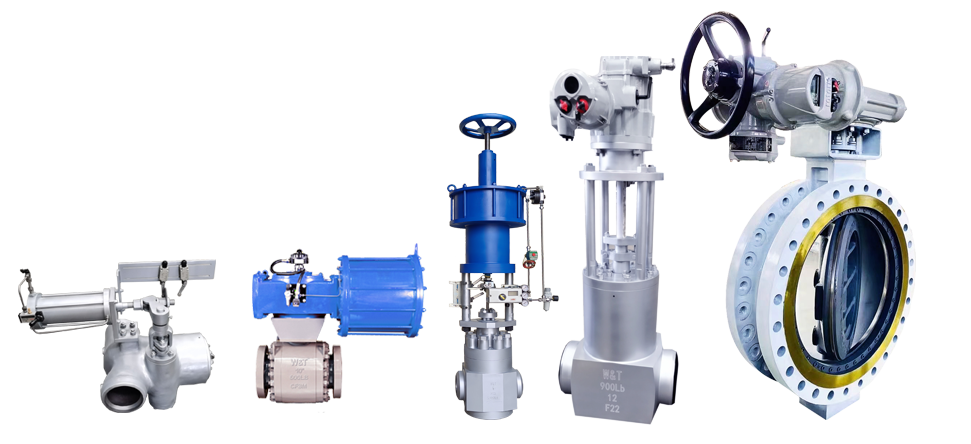

To address the issue of industrial valves' ability to withstand harsh working conditions, Viti Industrial strives for excellence and continuous research and development improvements, providing you with a variety of world-leading industrial valves that can meet the impact resistance requirements under harsh working conditions. Here are some examples for your illustration:

Viti Industries offers you our high-pressure differential steam trap regulating valves that are resistant to erosion under harsh working conditions at the world's leading technological level

1. The high-pressure differential steam drain regulating valve provided by Viti Industry is strictly designed in accordance with the ASMEB 16.34 standard. The valve diameter and throat diameter are consistent with the pipe diameter. Viti Industry firmly does not choose reduced-diameter products, minimizing the scouring caused by the excessive speed of the medium in the valve body to the greatest extent.

2. The high-pressure differential steam trap regulating valve provided by Viti Industry adopts integral free forging. The strength of the valve body is higher than that of die forging, and the structure is also more aesthetically pleasing.

3. The high-pressure differential steam trap regulating valve provided by Viti Industry has a small torque and can be easily opened and closed, which is conducive to the selection of the actuator.

4. The high-pressure differential steam trap regulating valve provided by Viti Industry adopts a non-rotating valve stem. During the lifting and lowering process of the valve stem, there is no rotation, which minimizes the wear of the valve stem on the packing to the greatest extent.

5. The high-pressure differential steam trap regulating valve provided by Vite Industry features an ultra-hard pressure-reducing sleeve design inside. When high-energy fluid media enter the valve, they collide with each other, significantly reducing their energy. Moreover, the internal volume of the valve body expands. According to Charles' Law, the pressure generated by the medium is further reduced. After the medium fluid goes through this series of expansion, collision and countercollision stages, the pressure can be reduced by 70%, which reduces the erosion of the medium on the valve internings. The unique pressure reducing sleeve design of Viti Industrial, compared with other steam traps, reduces the pressure difference and avoids the occurrence of cavitation.

6. The high-pressure differential steam trap regulating valve provided by Viti Industry features inner components made of ultra-thick hard alloy surfacing welding, which is highly hard and resistant to erosion. Once the valve is fully opened, the valve core will be completely protected by the pressure-reducing sleeve and will not be eroded by the medium.

7. The high-pressure differential steam trap regulating valves provided by Viti Industry will have different forms of pressure reducing sleeves depending on the working conditions. This depends on your specific medium and other circumstances. The number, position, and size of the pressure reducing holes, as well as the number of sleeve layers, all need to be specially designed according to the specific working conditions.

10. The high-pressure differential steam trap regulating valve provided by Viti Industry features a replaceable valve seat design. During unit maintenance, there is no need to cut the valve off the pipeline; it can be replaced and maintained online, saving you time and cost.

In conclusion: The high-pressure differential steam trap regulating valve provided by Viti Industry not only features an aesthetically pleasing design, but also strives for excellence in materials and structure, being resistant to erosion and high temperatures, aiming to make your use more worry-free.

Viti Industry offers you multi-stage pressure-reducing steam (feed water) control valves

The multi-stage pressure-reducing steam (feed water) control valves provided by Viti Industry are strictly designed in accordance with the ASME B16.34 standard. For valves above 1500Lb, forged valves are preferred.

2. The multi-stage pressure-reducing steam (feed water) control valve provided by Viti Industry adopts a large valve cavity structure. The medium does not exceed the speed limit inside the valve body, and the throat diameter is larger than that of the same product.

3. The multi-stage pressure-reducing steam (feed water) control valve provided by Viti Industry adopts a multi-stage pressure-reducing design (up to nine stages) to control the fluid flow rate, minimizing phenomena such as scouring, flash evaporation, and cavitation, and reducing vibration and noise.

4. The multi-stage pressure-reducing steam (feedwater) control valves provided by Viti Industry will have different openings in the labyrinth sleeve depending on the operating conditions of the valves. For some harsh working conditions or complex medium situations, the openings in the labyrinth will also be specially treated.

5. The multi-stage pressure-reducing steam (feedwater) control valve provided by Viti Industry is designed for high-pressure differential conditions and adopts a balanced valve core, ensuring balanced force during the opening process.

6. The internal components of the multi-stage pressure-reducing steam (feedwater) control valve provided by Viti Industry are hardened through high-temperature heat treatment to enhance the hardness of the valve assembly.

7. The sealing surface of the multi-stage pressure-reducing steam (feedwater) control valve provided by Vite Industry is welded with ultra-thick hard alloy to ensure that the valve sealing meets the MSS-SP-61 standard.

8. The actuator structure of the multi-stage pressure-reducing steam (feedwater) control valve provided by Viti Industry can be driven by electric, pneumatic or (electric) hydraulic power.

9. The multi-stage pressure-reducing steam (feedwater) control valves provided by Viti Industry feature replaceable valve seats. During unit maintenance, there is no need to cut the valves off the pipeline; they can be replaced and maintained online.

Iii. Minimum flow recirculation regulating valve for feed water Pumps provided by Viti Industry:

Viti Industry offers you the world-leading high-pressure three-eccentric all-metal hard-sealed quick-cut-off and regulating butterfly valve:

The high-pressure three-eccentric regulating butterfly valve provided by Viti Industry strictly complies with the ASME B16.34 design standard.

2. The high-pressure three-eccentric regulating butterfly valve provided by Viti Industry is suitable for rapid flow cut-off and regulation in high-pressure pipelines, with a maximum weight class of up to 2500Lb.

3. The high-pressure three-eccentric regulating butterfly valve provided by Viti Industry is flexible in opening and closing, has better performance than gate valves, and has high regulating performance. It can replace Globe type regulating valves.

4. The actuator of the high-pressure three-eccentric regulating butterfly valve provided by Viti Industry can be equipped with electric, pneumatic or (electric) hydraulic drive devices.

5. The high-pressure three-eccentric regulating butterfly valves provided by Viti Industry can be integrally forged from different superior materials according to the working conditions.

6. The high-pressure three-eccentric regulating butterfly valve provided by Viti Industry has a wide applicable temperature range, from -196℃ to 850℃, and can be applied in industries such as LNG, coal chemical engineering, power, refining and chemical engineering, and metallurgy.

7. The high-pressure three-eccentric regulating butterfly valve provided by Viti Industry adopts a three-eccentric design, featuring a small opening torque and excellent sealing performance.

8. The high-pressure three-eccentric regulating butterfly valve provided by Viti Industry ensures bidirectional pressure resistance, guaranteeing the bidirectional fluid cut-off and sealing of the medium in the pipeline.

9. The high-pressure three-eccentric regulating butterfly valve provided by Weitai Industry features an integral metal forged sealing ring and valve seat. Both the valve seat and the sealing ring are made by surfacing Stellite alloy or more suitable sealing materials for specific working conditions. The surfacing sealing ring has advantages such as wear resistance, erosion resistance, long service life, and good sealing effect, achieving zero leakage.

10. The high-pressure three-eccentric regulating butterfly valve provided by Viti Industry can have its sealing ring replaced on site. The sealing ring and valve seat can be removed as a set from between the valve bodies for replacement, eliminating the need to disassemble and replace the entire valve, thus enabling rapid on-site maintenance.

In addition to the above-mentioned classic products, Vite Industry also offers other types of valves, such as uniquely designed temperature and pressure reducing valves, high/low pressure relief steam trap regulating valves, desuperheating water regulating valves, double eccentric high-performance butterfly valves, Y-type stop valves, T-type stop valves, and a series of other classic valves.

Viti Industrial Valves offers you a one-stop professional solution for pipeline fluid control.

Demand feedback