news

德国维替阀门 2026-01-07 15:30 2218

In our work, many industries involving high-temperature and high-pressure steam, such as thermal power plants, petrochemicals, textiles, papermaking, food processing and other industrial fields, desuperheaters and pressure reducers are quite common and are an important device in thermal energy engineering. It is mainly used to stably and continuously adjust the high-temperature and high-pressure steam from boilers or heat networks to the lower pressure and temperature required by users through single-stage or multi-stage throttling expansion and water spraying for temperature reduction. The core of the device lies in the safe and precise conversion of thermal parameters.

Its structural principle can be decomposed into two core parts: "pressure reduction" and "temperature reduction", which are usually integrated into one device.

Main structural composition

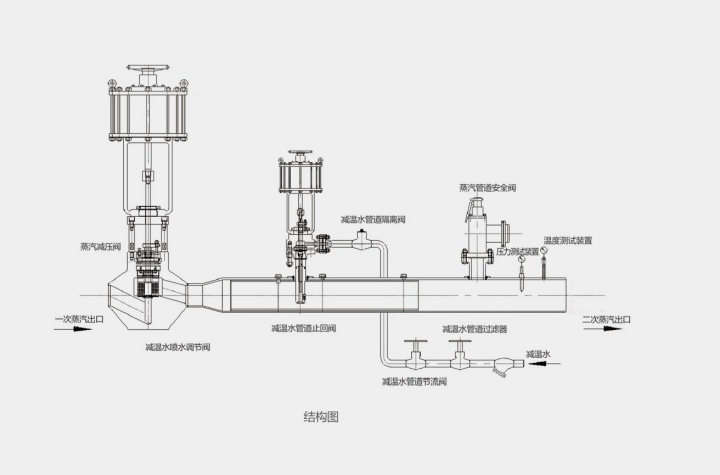

A typical desuperheater and pressure reducer is mainly composed of the following four major systems:

1. Pressure relief system

Core components: Pressure reducing valve (or regulating valve, throttle orifice plate).

Function: By changing the opening degree of the valve core, it throttles and expands high-pressure steam. When steam flows through a narrow flow cross-section, the flow rate increases sharply, and the pressure energy is converted into kinetic energy, thereby significantly reducing the pressure.

Key point: The essence of the pressure reduction process is an approximately adiabatic throttling process, with the enthalpy value remaining basically unchanged but the entropy increasing. When the pressure drops, the superheat of the steam will increase (for superheated steam) or the dryness will decrease (for saturated steam).

2. Cooling system

Core component: Thermostat (water spray device).

Structural form: Venturi tube type/atomizing nozzle type: The most common. Venturi tubes or atomizing nozzles are set up in the mixing pipeline. The negative pressure formed by the high-speed flow of steam at this location is utilized to draw in the deheated water and atomize it into extremely fine water droplets.

Vortex type: It generates a strong swirling flow of steam, which is thoroughly mixed with water.

Multi-hole nozzle type: Multiple small holes are arranged around the pipe to spray water.

Function: Atomize the precisely measured and pressurized demineralized water (usually demineralized water or condensate water) and evenly spray it into the depressurized steam flow. Water droplets instantly absorb the heat of the steam and completely evaporate, thereby reducing the temperature of the steam.

3. Safety and Control System

Pressure/temperature sensor: Real-time monitoring of the pressure and temperature of the steam at the outlet.

Control cabinet/regulator: Receives sensor signals, compares them with the set values, and outputs control instructions through algorithms such as PID.

Actuator (such as electric/pneumatic control valve) : According to the control instructions, precisely adjust the opening degree of the pressure reducing valve and the flow rate of the cooling water.

Safety valve: Installed on the outlet pipeline, when the control system fails and causes the outlet pressure to exceed the limit, the safety valve trips to release pressure and protect downstream equipment.

4. Main body pipeline system

Inlet steam pipe, mixing pipe (cooling section), and outlet steam pipe: They form the steam flow path.

The heating water connection pipe, filter, stop valve and regulating valve: they form the supply path of the heating water.

Drain system: Discharge the unevaporated condensate water during startup or at low load.

Working principle and process

The working principle of the desuperheater and pressure reducer follows the basic principle of "reducing pressure first, then reducing temperature", which is a sequential and coordinated process:

1. Inlet state: High-temperature and high-pressure superheated (or saturated) steam enters the device.

2. Pressure regulation

Steam first passes through the pressure reducing valve.

The control system automatically adjusts the opening degree of the pressure reducing valve based on the feedback from the outlet pressure sensor.

Reduced opening → Enhanced throttling effect → decreased outlet pressure. Increased opening → weakened throttling effect → elevated outlet pressure.

After pressure reduction, the steam pressure meets the requirements, but the temperature may be higher than the target value (due to the increase in superheat after throttling).

3. Temperature regulation

The depressurized steam enters the cooling section (mixing pipe).

The control system precisely calculates and adjusts the opening degree of the desuperheating water regulating valve based on the feedback from the outlet temperature sensor.

An appropriate amount of desalinated water, which has been pressurized (the pressure is usually higher than the steam pressure at that point), is sprayed into the center of the steam flow through an atomizing nozzle.

The atomized water droplets undergo intense heat and mass exchange with high-temperature steam. After absorbing the latent heat and sensible heat of vaporization, the water droplets completely evaporate.

The temperature of the steam drops as heat is carried away. By controlling the amount of water sprayed, the outlet temperature can be precisely and stably maintained at the set value.

4. Outlet status: Steam that meets the process requirements in terms of pressure and temperature is obtained and transported to the user end.

Principle summary

Pressure reduction principle: Fluid throttling effect (Joule-Thomson effect). Pressure energy is consumed through local resistance to achieve pressure reduction. This process is approximately isenthalpic but irreversible, resulting in a decrease in the working capacity of the steam (exergy loss).

The principle of temperature reduction: Direct contact heat exchange and mixture of substances. The steam temperature is reduced by using atomized water to absorb the heat of the steam and vaporize it. This is a process of adjusting the dryness or superheat of steam.

Control principle: Closed-loop feedback control. Pressure control and temperature control are two independent but interrelated closed-loop circuits that work together to stabilize the outlet parameters.

Technical key points and features

Atomization quality: The atomization effect of desuperheating water is of vital importance. The better the atomization, the larger the surface area of water droplets, the faster the evaporation rate, avoiding water carry-over and ensuring the quality of steam.

Pressure-temperature coupled control: The pressure reduction and temperature reduction processes interact with each other, requiring advanced control strategies (such as decoupling control) to avoid oscillation and achieve rapid stability.

Materials and protection: Key components such as the valve core, valve seat, and nozzle need to be resistant to high temperatures and erosion. Anti-erosion bushings are often found inside the mixing tube.

Operating range: It is required to operate stably within the design range (such as 30%-100% load).

Application field

It is widely applied in industrial fields such as thermal power plants, petrochemicals, textiles, papermaking, and food processing, providing reliable steam sources for various process equipment that require steam of different parameters, such as heating, drying, reaction, and driving steam turbines.

In short, the desuperheater and pressure reducer is an intelligent thermal parameter "regulation station". Through precise mechanical structure and automatic control system, it processes high-pressure and high-temperature "coarse grain" steam into low-pressure and low-temperature steam that is suitable for users' equipment to "chew slowly".

Demand feedback