ballvalve

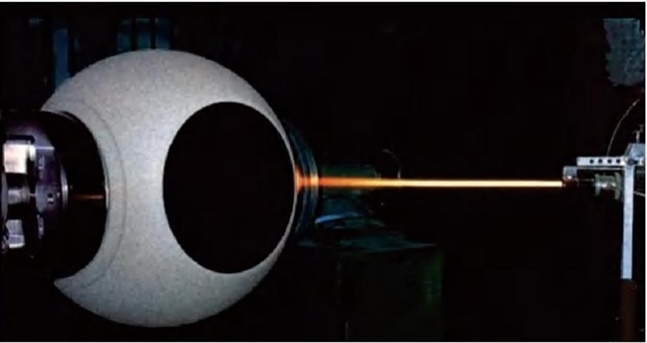

The wear-resistant ball valves provided by Viti Industry can be processed by supersonic spraying technology. The ball core can be sprayed with SiC or SiN by supersonic plasma beam flow on the surface of the ball core. After spraying, there is generally a 3-5mm thick layer of relatively hard SiC or SiN ceramic layer on the surface of the ball core, which improves the surface hardness and corrosion resistance. It features a reasonable design of the sealing preload, flexible opening and closing, and effective guarantee of the reliability of the seal.

Design features of wear-resistant ball valves provided by Viti Industry:

1. The sealing preload is reasonably designed and opens and closes flexibly, effectively ensuring the reliability of the seal.

Second, it features low torque, small valve seat deformation, stable sealing performance and long service life.

Three. It is suitable for scenarios with large diameters, high temperature and high pressure, and excessive pressure difference before and after the valve.

4. Spring pre-valve seat assembly, with self-tightening characteristics, achieves upstream sealing;

V. Design of isolation between the sealing surfaces of the ball and the valve seat and the medium;

Six. Weld stellite to the surface of the sphere or use plasma supersonic spraying.

Seven. Bottom-mounted anti-blowout valve stem, fixed ball valve, with a lower valve stem and strong high-pressure resistance.

8. Fireproof and anti-static design, self-pressure relief function of the valve cavity, and reasonable opening and closing torque design;

Ix. The switch is easy to operate, with valve seats in both directions, and the medium flow direction is not restricted. It is particularly suitable for some cut-off working conditions where the switch time cannot be too long and the pressure difference before and after the valve is large.

The wear-resistant ball valves provided by Viti Industry are applied in the following industries:

Energy and environmental protection: desulfurization and denitrification, three-waste treatment, fly ash removal, zero discharge of wastewater;

Steel and metallurgy: Coal injection in blast furnaces, ash and dust removal, desulfurization in sintering machines, carbon injection in electric furnaces, pretreatment of molten iron;

Hydrometallurgy: casting, mining and mineral processing, non-ferrous smelting, molding sand transportation, slurry regulation;

Petrochemical industry: Acidic mixture of catalytic cracking drilling mud

Coal chemical engineering: Fly ash/water coal ash, conveying black water/ash water/chilled water slag water, regulating synthesis/shift system;

Silicon chemical engineering: Silicon powder conveying/venting, slurry/residual liquid treatment, first, second and third spin separators, venting of fine powder tanks;

Salt chemical engineering: calcium carbide slurry, salt mud, lime milk, ammonia brine, sulfuric acid, hydrochloric acid, liquid chlorine;

Mining and smelting: Tailings backfilling, slurry/sand transportation, oxidation/smelting/electrolysis.

Viti Industrial Supersonic spraying process

For some special working conditions, the surface of the ball core can be sprayed with SiC or SiN using supersonic plasma beam flow. After spraying, the surface of the ball core is generally coated with a 3-5mm thick layer of relatively hard SiC or SiN ceramic, which increases the surface hardness and enhances the ball core's resistance to fluid corrosion.

The performance parameters of wear-resistant ball valves provided by Viti Industry

| Name |

Parameters |

| Nominal diameter | 1/2 "-48" (DN15 - DN1200) |

| Pressure level | CLASS 150-2500 |

| Temperature range | - 40 ℃ ~ 540 ℃ |

| Valve body material | WCB, A105, CF8, CF3, CF8M, CF3M, Monel alloy, Hastelloy, Incoel alloy |

| Internal component material | Ball cores: CF8+STL, CF8M+STL, CF3+STL, CF3M+STL CF8+ Plasma supersonic SiC silicon carbide spraying, CF8M+ plasma supersonic SiC silicon carbide spraying CF3+ plasma supersonic SiC carbide spraying, CF3M+ plasma supersonic SiC carbide spraying CF8+ Plasma supersonic SiN silicon nitride Spraying, CF8M+ Plasma supersonic SiN silicon nitride Spraying CF3+ Plasma supersonic SiN silicon nitride Spraying, CF3M+ Plasma supersonic SiN silicon nitride spraying Valve seats: CF8+STL, CF8M+STL, CF3+STL, CF3M+STL |

| Operation mode |

Manual worm gear boxes, pneumatic, electric, hydraulic, etc. |

| Connection form |

Flanged type, butt welding, threaded |

Demand feedback