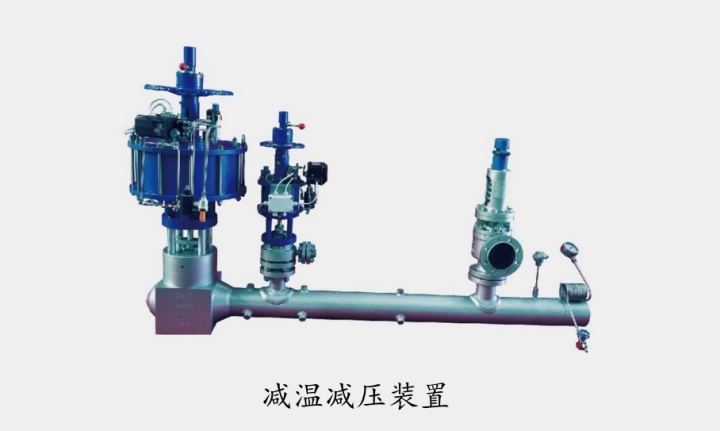

jianwenjianya

Description of the purpose of the temperature and pressure reducing device:

The fluid control adopts a temperature and pressure reducing valve structure, enabling the steam temperature and pressure reduction to be carried out within the same valve and shortening the structural length. The use of single-seat feedwater regulating valves or high-pressure differential feedwater regulating valves can be combined with the pressure difference on the distribution feedwater system. It is used for medium temperature, medium pressure and sub-high temperature and high pressure parameters.

The structure of the temperature and pressure reducing device provided by Viti Industrial Valves:

The temperature and pressure reducing system is composed of four parts: the pressure reducing system, the temperature reducing system, the safety protection device and the automatic control device.

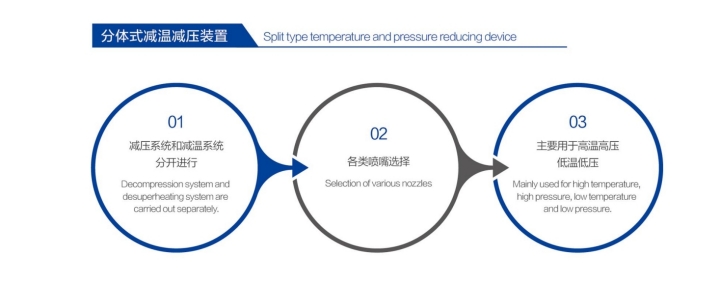

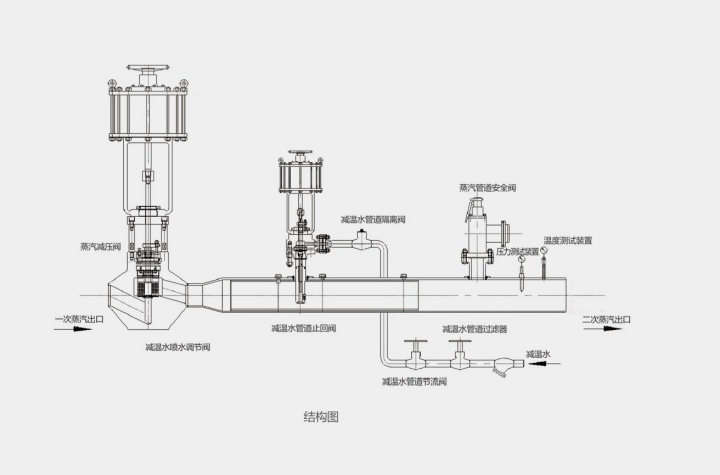

Ii. Pressure Reducing System - Through pressure reducing valves and throttling orifice plates, multi-stage throttling technology is adopted to reduce the pressure of the primary steam to the pressure required by the user.

Iii. Desuperheating System - Mechanical atomizing nozzles are used to spray water onto high-temperature steam to achieve the purpose of reducing the steam temperature.

The regulation of steam temperature is achieved by the actuator controlling the opening degree of the water spray desuperheater. The desuperheater adopts adjustable nozzles to achieve a good atomization effect. Safety protection device - It is directly achieved by using impulse safety device (composed of main safety valve and impulse safety valve) or spring safety valve. When the secondary steam pressure exceeds the set value, the overpressure part of the steam is discharged to the atmosphere, thereby keeping the secondary steam pressure within the allowable value.

4. Automatic Control Device - Used to control the steam pressure and temperature, keeping the secondary steam pressure and temperature within the required set values.

V. Safety Protection Devices - The impulse safety device (composed of the main safety valve and the impulse safety valve) or the spring safety valve is directly adopted to achieve this. When the secondary steam pressure exceeds the set value, the overpressure part of the steam is discharged to the atmosphere, thereby keeping the secondary steam pressure within the allowable value.

The technical parameters of the temperature and pressure reducing device provided by Viti Industrial Valves

| Nominal diameter | DN15-DN750 (1/2-30 inches) |

| Pressure level | CLASS 150-2500 |

| Applicable temperature | - 29-550 ℃ |

| Valve body material | WCB/WCC/WC6/WC9/A105/CF8/CF8M/CF3/CF3M/F22/F91 |

| Internal component material | 304+STL, 304L+STL, 316+STL, 316L+STL |

| Connection method |

Fran |

| Transmission mode |

Manual, pneumatic, electric |

Demand feedback